ProTec show premiere at Fakuma: manufacturing solution for new “SOMOS

Perfoamer” physical foaming process achieves material savings of up to 60 per cent

- Partners: Kunststoff-Institut Lüdenscheid and Linde AG

- Easily combined with existing injection molding machines

Bensheim, 24 July 2018. ProTec Polymer Processing GmbH is premiering the “SOMOS

Perfoamer” manufacturing solution at this year’s Fakuma. This enables the new

“PLASTINUM Foam Injection Molding” process presented by Kunststoff-Institut Lüdenscheid

and Linde AG in 2017 to be used for physically foaming plastics parts on an industrial scale.

ProTec’s innovation includes all the components for drying and temperature adjusting

polymer pellets, loading them with CO2 under pressure and then feeding them to any desired

injection molding machine, which generally requires no modification. From 16 to 20 October,

ProTec will be carrying out live foaming demonstrations using the “SOMOS Perfoamer” and

an Engel e-victory 310/80 injection molding machine at Fakuma, hall B3, booth 3119.

It will also be showing smart, Industry 4.0 capable SOMOS components for efficient

conveying, drying, dosing and mixing as well as presenting its LFT pultrusion lines for

manufacturing long fiber reinforced thermoplastics.

“SOMOS Perfoamer” – modular structure means easy scalability

Its modular structure means the “SOMOS Perfoamer” can easily meet changing

requirements and be expanded with additional components. As a result, output volume can

easily be scaled to supply different sizes of injection molding machines or a number of

machines at the same time.

The demonstration system at the booth can supply a throughput of up to 59 kg/h of

polycarbonate or up to 45 kg/h of polypropylene. The system will be demonstrated live

manufacturing bottle openers from a variety of polymers with a shot weight of 42 grams.

Since the bottle opener also has a metal insert, the overall cycle time is 135 seconds.

Demonstration systems for the new physical foaming process using ProTec’s “SOMOS

Perfoamer” will also be shown at the partners’ booths: Linde AG (hall B3, booth 3309) and

Kunststoff-Institut Lüdenscheid (hall 5, booth 5312).

About ProTec:

ProTec Polymer Processing GmbH is an international one-stop shop supplier to the plastics

industry with a focus on injection molding, extrusion and blow molding. Its range of services

covers components, solutions and turn-key systems for efficient materials handling,

treatment and recycling of plastics and for manufacturing long fiber reinforced thermoplastics

using LFT pultrusion lines. Managed by Peter Theobald and Dirk Egemann, the company

has some 120 staff and is based in Bensheim, near Darmstadt, Germany.

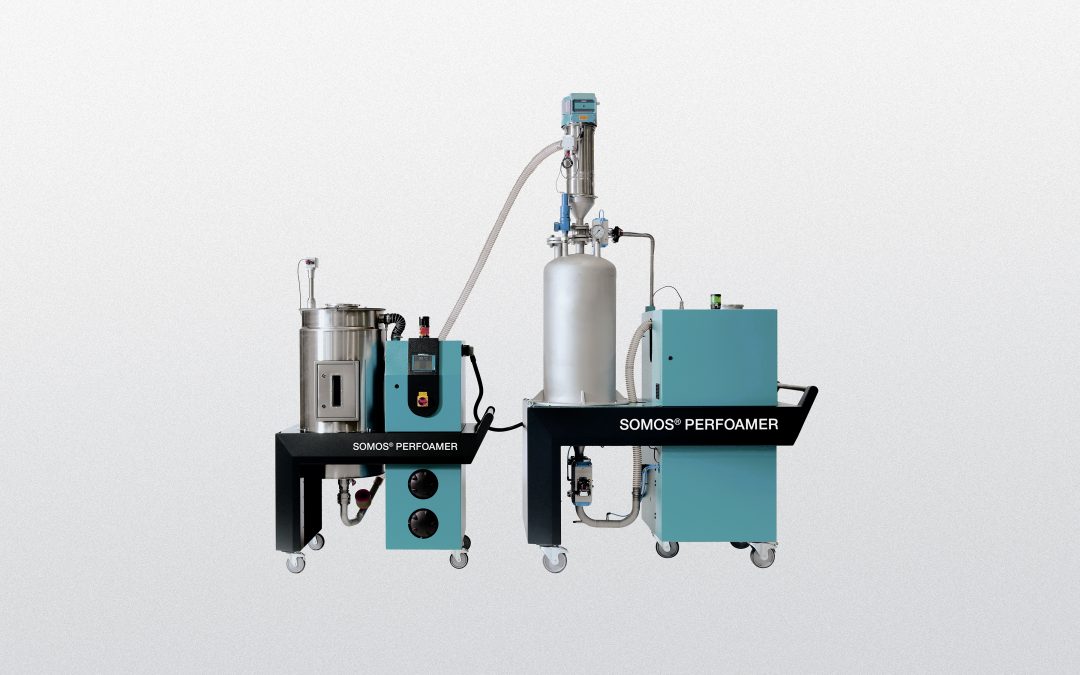

Photo 1:

ProTec’s “SOMOS Perfoamer” includes all the components for drying and temperature

adjusting polymer pellets, loading them with CO2 under pressure and then feeding them to

any desired injection molding machine, which generally requires no modification (photo:

ProTec Polymer Processing).

Photo 2:

Using ProTec’s “SOMOS Perfoamer”, the new “PLASTINUM Foam Injection Molding”

process presented by Kunststoff-Institut Lüdenscheid and Linde AG in 2017 can for the first

time be used for physically foaming plastics parts on an industrial scale (photo: ProTec

Polymer Processing).

Photo 3:

Using “SOMOS Perfoamer” and an Engel e-victory 310/80 injection molding machine,

ProTec will carry out live demonstrations of bottle opener production at Fakuma, booth 3119,

hall B3 (photo: Kunststoff-Institut Lüdenscheid).